Welding is an essential process in countless industries, from automotive manufacturing to construction and shipbuilding. While it’s indispensable, welding also introduces significant health and safety risks through the release of fumes, gases, and fine particles. These contaminants can linger in the air, exposing workers to respiratory hazards and contributing to long-term health conditions. For this reason, many facilities have turned to a targeted solution: the source capture arm.

What Is a Source Capture Arm?

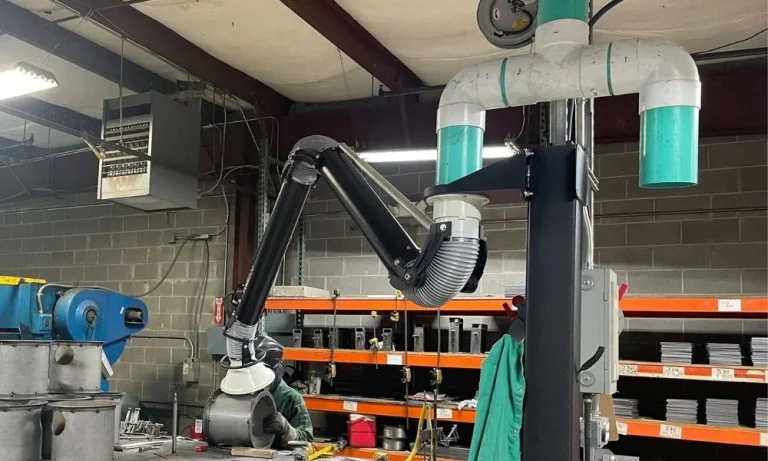

A source capture arm is a flexible extraction device designed to remove fumes, dust, and airborne contaminants directly at their point of generation. Instead of relying on general room ventilation, the arm is positioned close to the welding arc, where it collects hazardous fumes before they disperse into the workspace. The captured air is then filtered or vented, depending on the system design.

Protecting Worker Health

The primary benefit of using a source capture arm is improved worker health. Welding fumes can contain metals such as manganese, chromium, and nickel, as well as gases like ozone and carbon monoxide. Even short-term exposure can cause irritation of the eyes, nose, and throat, while long-term exposure has been linked to serious conditions, including lung disease and certain cancers. By removing fumes at the source, capture arms significantly reduce the concentration of harmful substances in the air workers breathe.

Compliance with Safety Standards

Regulatory bodies such as OSHA and ANSI require employers to control airborne hazards in the workplace. Source capture arms help facilities meet these standards more effectively than relying on general ventilation alone. Because the arms target fumes before they spread, they provide a level of control that aligns closely with industrial hygiene best practices. This proactive approach not only helps companies avoid fines but also demonstrates a clear commitment to worker safety.

Flexibility and Efficiency

Another advantage of source capture arms is their adaptability. They are designed to be highly flexible, allowing welders to position them exactly where extraction is needed. Many arms are equipped with adjustable joints and swivel bases, making them easy to maneuver without disrupting workflow. This mobility ensures that workers can maintain efficiency while still benefiting from clean air.

Protecting Equipment and Work Quality

Welding fumes don’t just affect people — they can also settle on machinery, tools, and finished products. Over time, this buildup can damage equipment, reduce visibility in the work area, and compromise weld quality. By capturing fumes directly at the source, capture arms help maintain cleaner workspaces and protect valuable assets.

Cost Considerations

While installing a source capture arm may represent an upfront investment, the long-term financial benefits are significant. Cleaner air reduces employee absences, lowers healthcare costs, and minimizes wear on machinery. Facilities that prioritize effective fume control also tend to experience higher worker morale and retention, which further strengthens overall productivity.

Final Thoughts

Welding will always involve some level of risk, but those risks can be managed effectively with the right tools. A source capture arm is one of the most efficient and practical methods for controlling airborne hazards in welding applications. By capturing fumes before they spread, these systems protect workers, improve compliance, and support cleaner, more efficient operations. For industries that depend on welding, source capture arms represent not just an option but a best practice in modern air quality management.